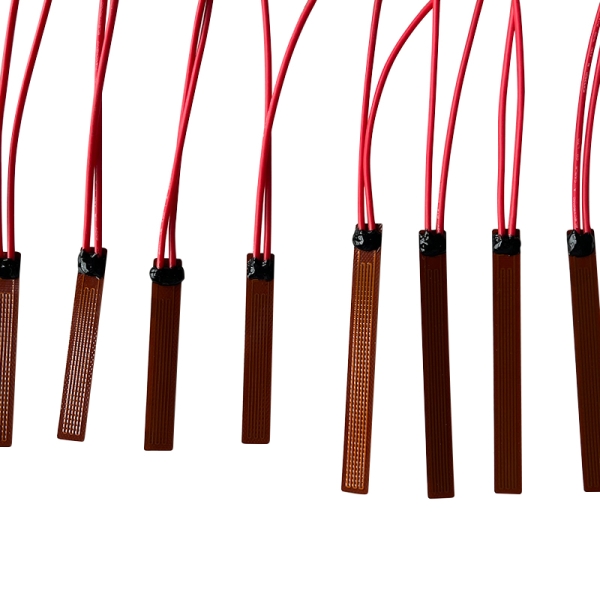

Polyimide Heater

Lens Optics Heater

Polyimide film heaters are widely used in lenses and optical components, mainly for defrosting, preventing condensation and temperature control. This heater can provide uniform heat distribution for o

Product Introduction

Polyimide film heaters are widely used in lenses and optical components, mainly for defrosting, preventing condensation and temperature control. This heater can provide uniform heat distribution for optical equipment to maintain clear image quality and optical performance, especially in environments with drastic temperature changes or cold and humid environments. The following are its specific applications in lenses and optical components:

1. Prevent lens frost and condensation

Defrosting and anti-condensation: In cold environments or environments with high humidity, frost or water vapor condensation is easy to form on the surface of the lens, affecting the imaging effect. Polyimide film heaters can transfer heat to the surface of the lens through surface bonding heating, prevent the formation of condensed water, and keep the lens dry and clean.

Maintain clear imaging: Since optical equipment requires high-resolution imaging effects, frost or condensation can cause blurred vision and light refraction problems. Film heaters provide uniform heating to ensure that there is no water vapor interference on the lens surface, thereby improving imaging clarity.

2. Accurate temperature control to ensure stable optical performance

Temperature stability: In an environment with large temperature fluctuations, the material of the lens may change its optical properties due to thermal expansion and contraction, resulting in changes in focal length or image quality. Polyimide film heaters can provide stable temperature control and maintain the optical stability of the lens. They are suitable for aerospace photography instruments, monitoring equipment and other optical imaging systems that require long-term reliability.

Prevent thermal stress: Some precision lenses are prone to thermal stress when the temperature changes suddenly. The low-power stable heating characteristics of polyimide film heaters can prevent stress in optical components caused by rapid heating or cooling.

3. Application in high-precision optical devices

Telescopes and cameras: In telescopes or high-magnification cameras, polyimide film heaters are used to heat the front end of the lens to avoid fogging or frost on the lens during long-term outdoor shooting. Such applications usually require the heater to be thin and light to keep the overall weight of the equipment light and meet the carrying requirements.

Microscopes: In the fields of biological experiments, microelectronic imaging, etc., high-precision microscopes may affect the observation of samples due to temperature changes. Polyimide film heaters can ensure that the lens and optical components operate at a stable temperature, improving the stability and accuracy of observation.

4. Suitable for optical equipment in special environments

UAVs and outdoor monitoring: UAVs and outdoor monitoring systems need to work in various harsh environments. Polyimide film heaters provide continuous heating around the lens to prevent lens fogging or frost caused by low temperatures, ensuring clear images.

Aerospace equipment: In space or high-altitude environments, the temperature is extremely low and changes dramatically. Optical equipment is prone to frost or condensation due to temperature differences. Polyimide film heaters can work stably under vacuum and low temperature conditions, providing temperature control support for aerospace optical equipment and maintaining the imaging quality of the equipment.

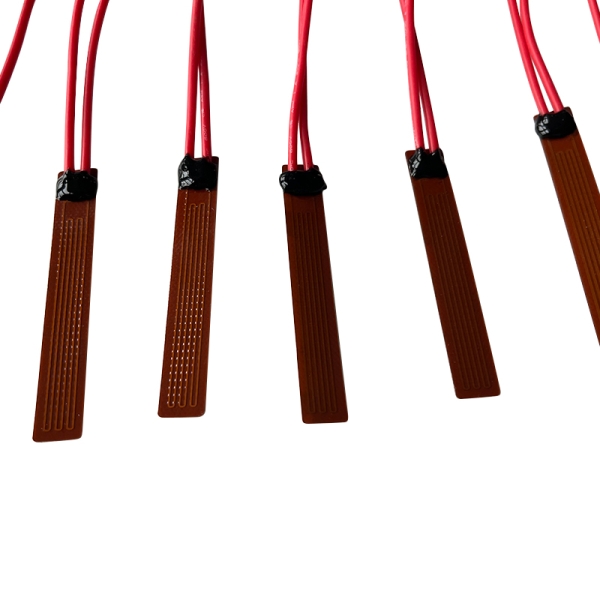

5. Flexible and lightweight, with strong fit

Customized shape: Polyimide film heaters can be customized according to the shape of the lens or optical component. The heating film can fit the lens housing and provide uniform heat distribution without affecting the normal function of the optical component.

Lightweight and space-saving: Polyimide film is extremely thin and light, suitable for optical equipment that needs to reduce weight and has limited space. It can meet the heating needs of the equipment without increasing the volume or weight of the lens.

6. Durability and safety

Radiation resistance and temperature difference resistance: Polyimide materials have good radiation resistance and high temperature stability, and can remain durable in extreme environments. They are particularly suitable for optical equipment in aerospace or harsh ground environments.

Safe and efficient: Polyimide film heaters have insulating properties, reducing the risk of short circuits. Its low power consumption makes it more energy-efficient during long-term heating, and is suitable for devices with high battery life requirements.

Summary

Polyimide film heaters are widely used in lenses and optical components due to their adaptive, lightweight and durable characteristics, especially for preventing lens fogging, frosting, and stable temperature control. Its precise temperature control and uniform heating provide stable support for optical imaging. It is widely used in telescopes, microscopes, drone cameras and other equipment that require precise imaging. It is an extremely reliable heating solution in optical systems.