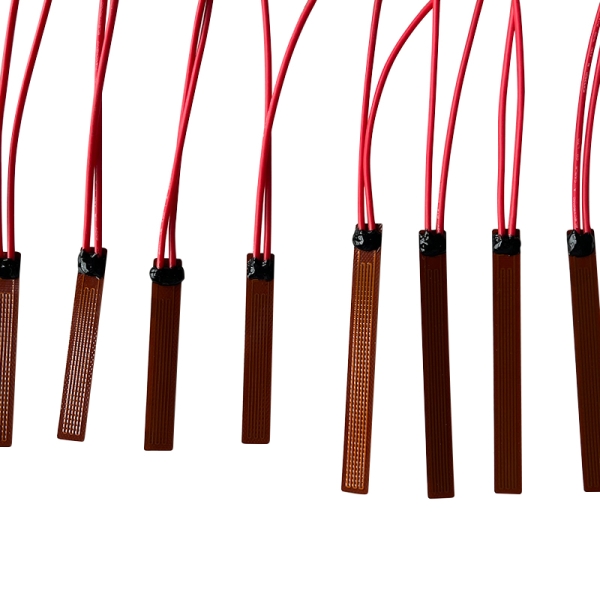

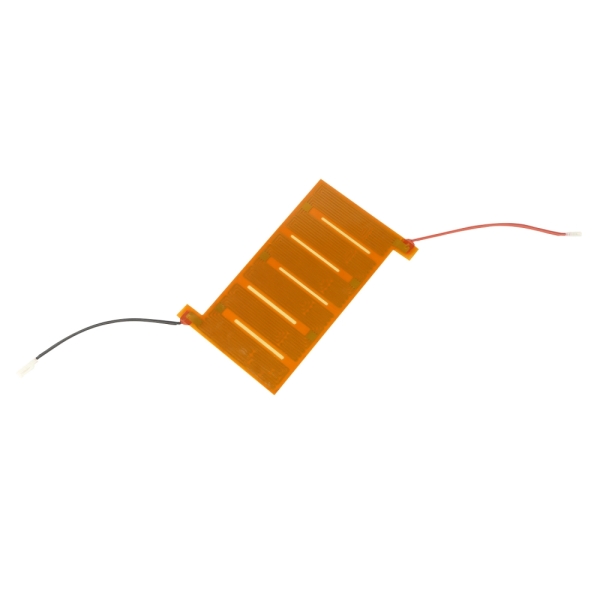

Polyimide Heater

Battery heater

The situation and advantages of polyimide film heaters in lithium battery heating applicationsPolyimide film heaters are widely used in the heating field of lithium batteries due to their ultra-thin,

Product Introduction

The situation and advantages of polyimide film heaters in lithium battery heating applications

Polyimide film heaters are widely used in the heating field of lithium batteries due to their ultra-thin, high temperature resistance, uniform heating and other characteristics. Especially in cold environments, they provide stable temperature support for lithium batteries and ensure stable output of battery performance. .

Application

Battery preheating in low-temperature environments In cold climate conditions, the chemical reaction rate of lithium batteries will significantly decrease, resulting in reduced discharge efficiency. The polyimide film heater can quickly raise the battery temperature to a suitable operating temperature to avoid battery capacity loss and performance degradation under low temperature conditions. This heating method is commonly used in lithium battery systems that need to operate at low temperatures, such as electric vehicles (EVs), drones, and portable devices.

Battery Temperature Maintenance In winter or low-temperature operating environments, polyimide film heaters are used to maintain battery temperature to ensure that the battery maintains stable output throughout the operation. This is especially important for battery systems that work for a long time, such as remote monitoring equipment, outdoor communication base station equipment, etc.

New energy storage system Polyimide film heaters also play an important role in lithium battery heating in the field of new energy storage, especially in solar and wind energy storage systems. Since the energy storage system is installed outdoors and is easily affected by low temperatures, the application of heaters can ensure the long-term stability of the energy storage system.

Special field applications: In some fields that require high battery performance, such as aerospace, marine equipment, etc., polyimide film heaters can provide precise temperature control for lithium battery systems to ensure battery reliability and safety.

Advantages of polyimide film heaters

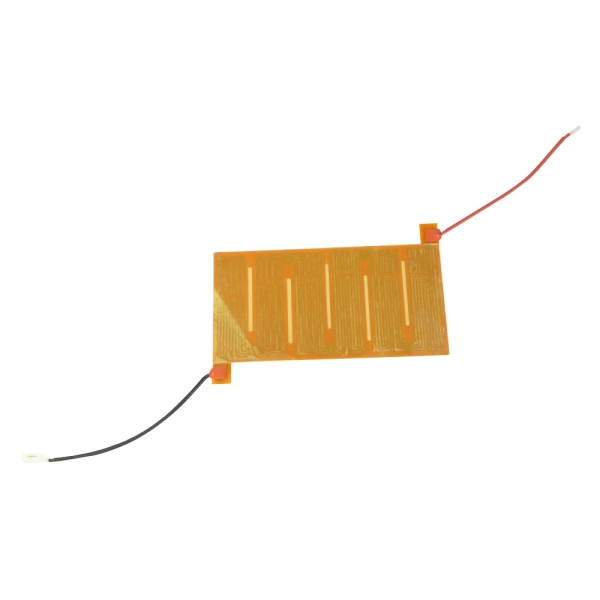

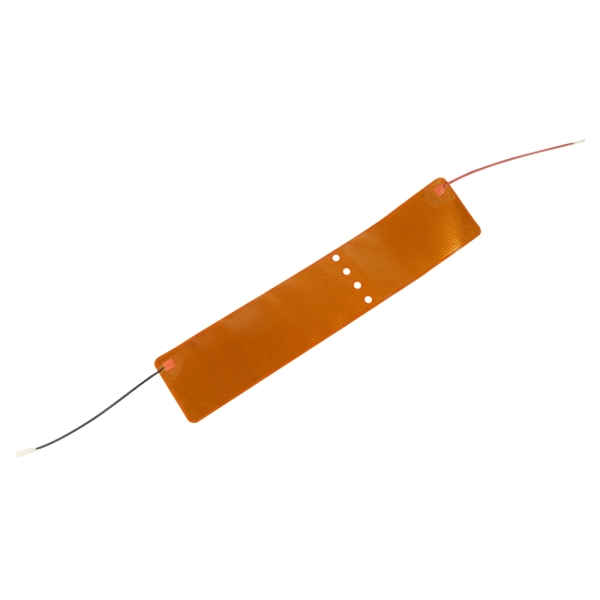

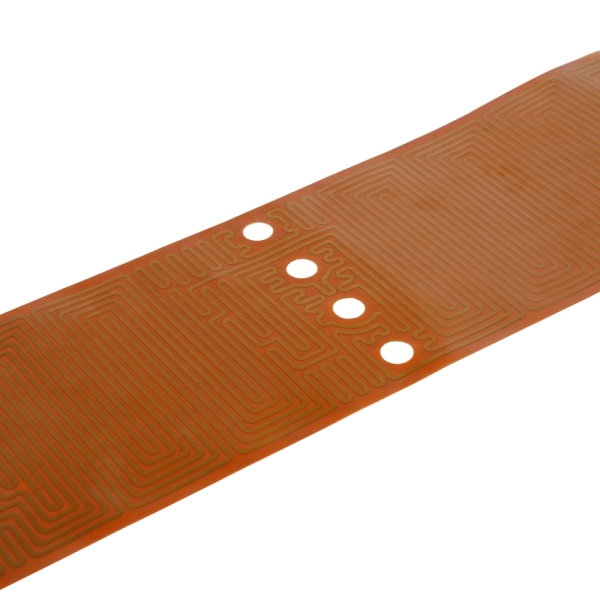

Uniform heating and rapid heating. The polyimide film heater has a good uniform heating effect, and the heating elements are thin and dense. It can reach the required temperature in a very short time, avoiding safety hazards caused by heat concentration and helping The lithium battery returns to working condition in a relatively short period of time.

Ultra-thin design and flexible installation. The thickness of polyimide film heaters is usually only 0.1-0.3 mm, which makes it easy to fit and install on the surface of the lithium battery pack. It takes up very little space and does not affect the structural design of the battery pack. This design allows it to be flexibly used in various complex structures or small spaces, and is especially suitable for battery systems with lightweight and high-efficiency requirements.

High temperature resistance and good insulation properties Polyimide materials have excellent high temperature resistance, and the operating temperature range is usually -200°C to 260°C. Its excellent insulation performance allows the heater to work safely under high temperature conditions, avoiding the risk of leakage or short circuit, and meets the high safety requirements of lithium batteries for heating systems.

High energy efficiency, energy saving and environmental protection. Polyimide film heaters have high heat conversion efficiency, can quickly reach and maintain the required temperature, and reduce power consumption. Its stable heating characteristics not only reduce energy consumption costs, but also extend the service life of lithium batteries and improve the efficiency of energy use.

Long service life: Due to the strong chemical stability of polyimide material, the heater is not easy to age and deteriorate under harsh conditions such as high temperature and humidity, and is suitable for long-term and frequent use. Its long life characteristics are especially suitable for lithium battery systems that require reliability to ensure stable operation of equipment.

Precise temperature control Polyimide film heaters can be used with intelligent temperature control systems to achieve precise temperature regulation and control. The temperature control system can monitor and adjust the temperature of the heater in real time to prevent battery overheating or temperature fluctuations and ensure that the lithium battery is in the most suitable operating temperature range.

Summarize

Polyimide film heaters are widely used in heating and temperature maintenance of lithium batteries because of their excellent temperature control performance and safety. They can effectively improve battery performance in low-temperature environments and extend battery life. At the same time, the ultra-thin design and high-efficiency characteristics make it an ideal heating solution in various lithium battery application scenarios, including electric vehicles, energy storage systems and outdoor equipment, etc., providing stable operation of lithium batteries under extreme temperatures. Reliable guarantee.